Dairy

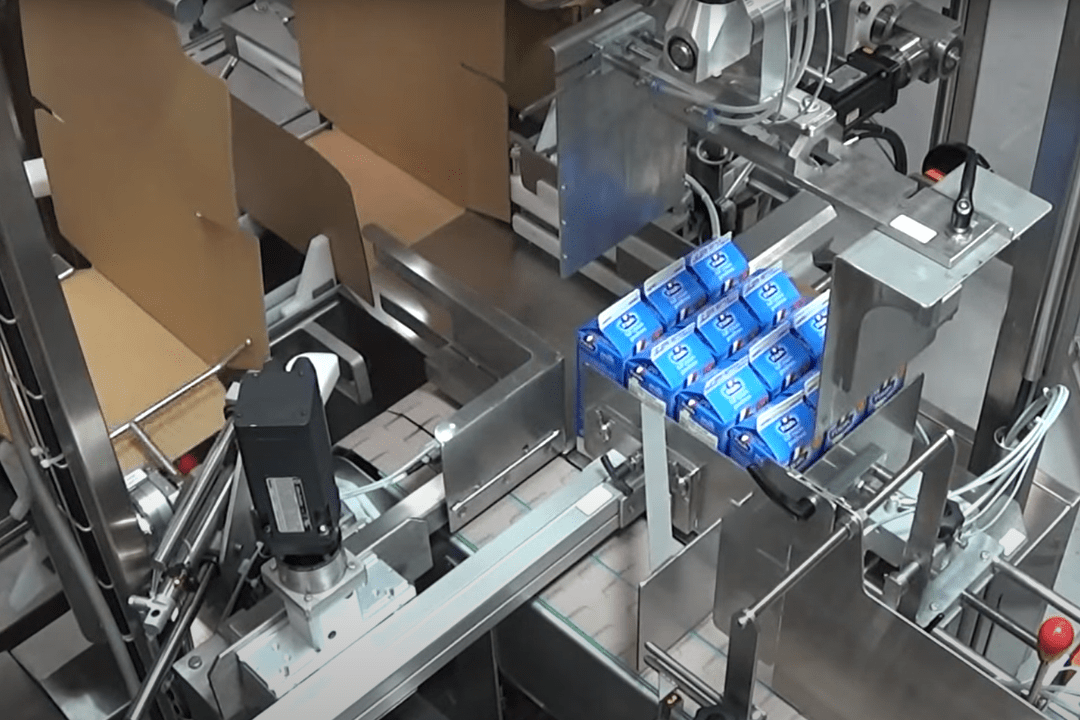

Video of HMPS Wraparound Casepacker for Pouches of Dairy Snacks. This HMPS 5000 is an automatic adjust wraparound casepacker designed to pack various pouches into a carton, which is formed and sealed with hot melt adhesive before being discharged to await palletisation. Operating at an infeed speed of 160 pouches per minute

2017 Award Winner – HMPS5000 Wraparound Case Packer. This HMPS packing solution is designed to automate the packaging requirements for customers who have a range of product weights, shapes and sizes they need to cater for. In this particular example you will see a packing solution for multivac blocks of cheese – weighing in

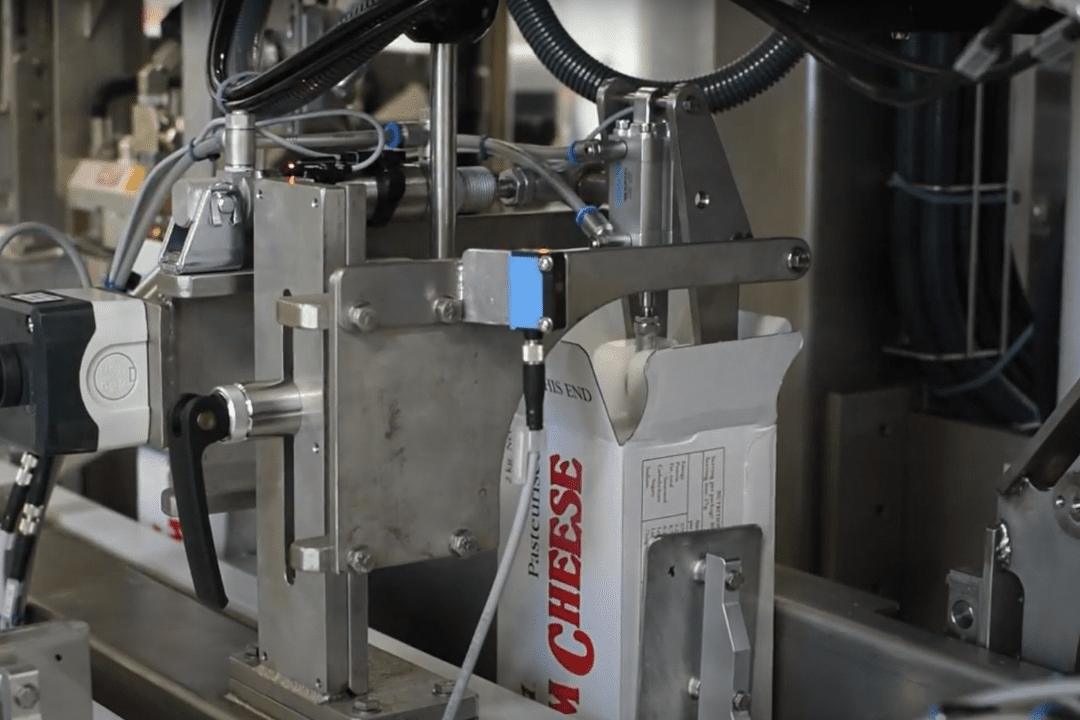

HMPS 1000 is a machine with integrated VFFS. It is designed to erect, load and seal an RSC carton containing a 2kg bag of cream cheese. Of particular interest in this project is the system integration. This video shows the bag in box that HMPS designed. It integrated their end of line packaging to work

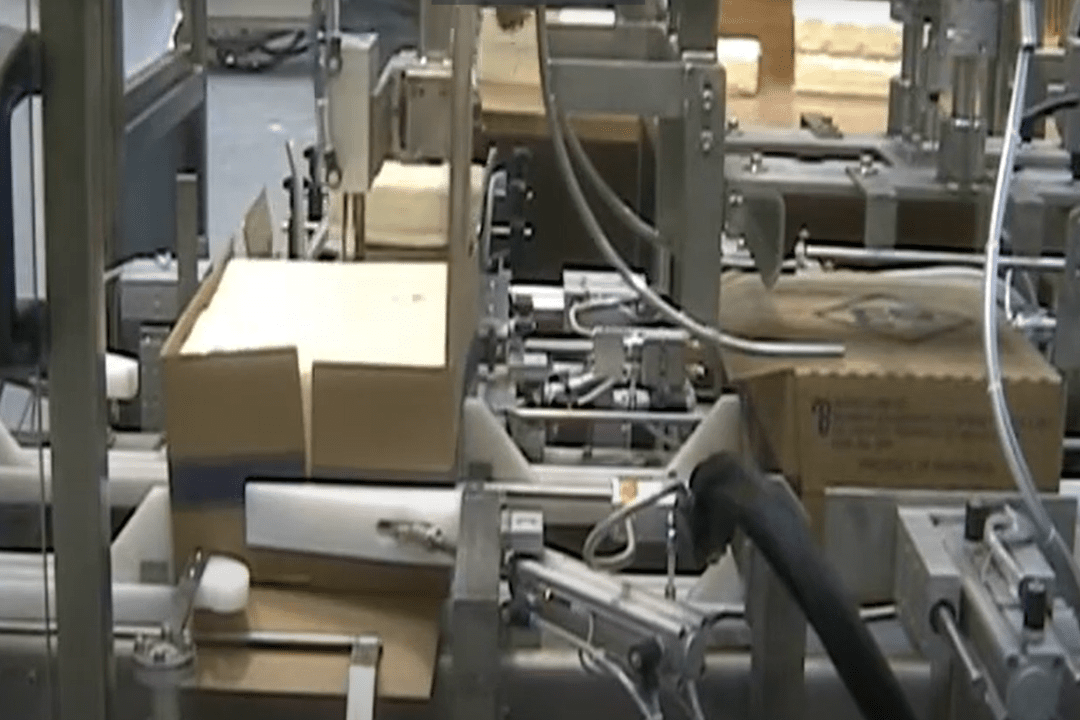

This HMPS5000 Wraparound Casepacker was designed and built by HMPS for one of our customers in the dairy industry. It was designed to enable the packing of various sizes and shapes of tubs of dairy products. In this particular design we had to take into consideration that the design of tub lids would not

Our client needed a sleever for their products. HMPS designed a Sleeve Flow Wrapper to collects and packs tubs of yoghurt to meet the requirement

A large dairy manufacturer in Brisbane required a turnkey system consisting of a wraparound casepacker and conveyor for packing their gable top milk cartons and also future packing of PET bottles into shelf-ready cartons. HMPS designed and installed a fully automatic case packer which currently packages tetra cartons: 300 mL, 600 mL and 1000