Dairy

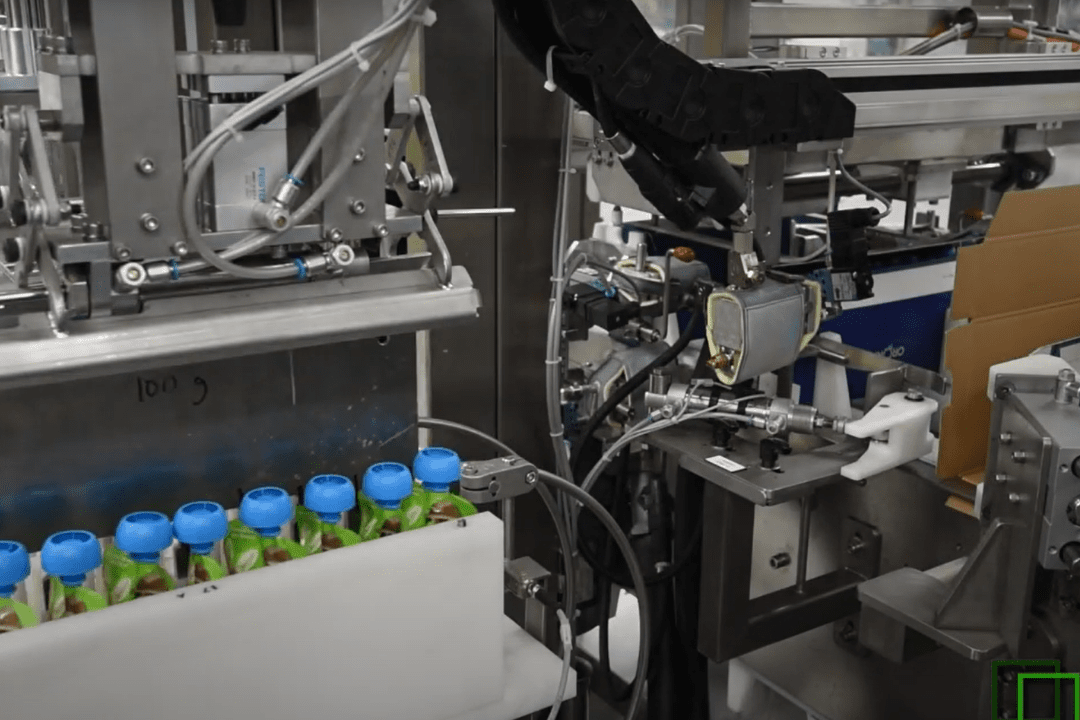

HMPS5000 Wraparound Casepacker is Packing a wide range of bottles of flavoured milk. This machine is able to pack anything from 500ml to 2000ml at high speed. Bottles are transfered onto the machines infeed conveyor and diverted from a single lane into a multi lane system to create the required number of columns. The required

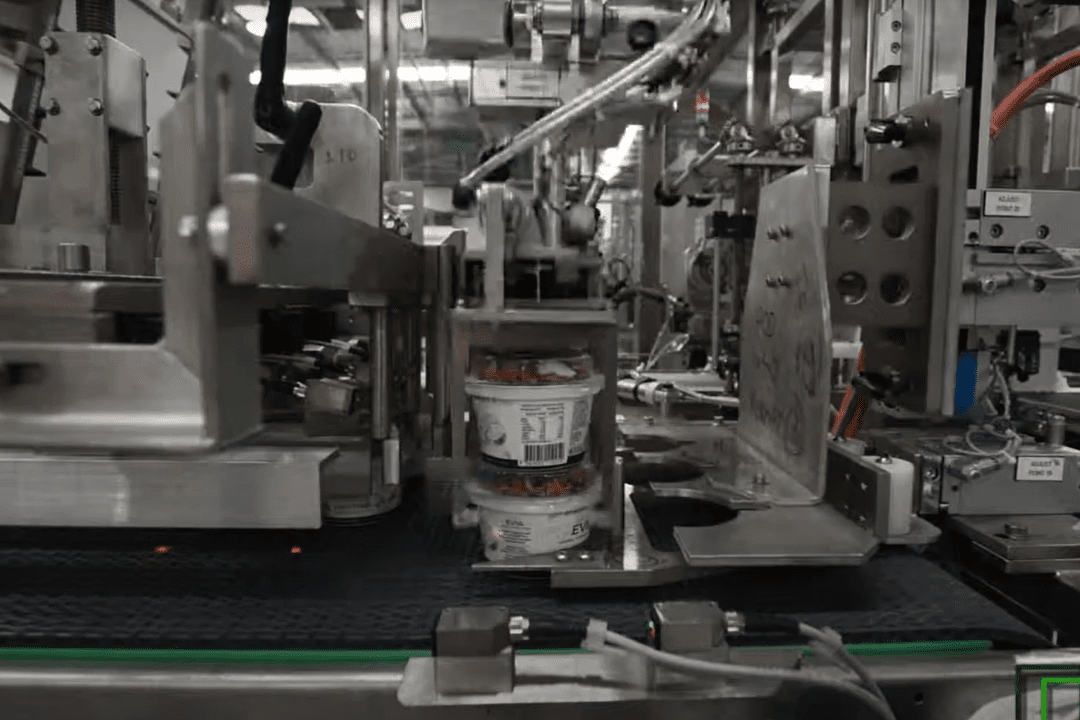

This HMPS 5000 is a manual adjust Wraparound Casepacker for packing pre-packed chilled snack meals as tubs of yoghurt. Tubs arrive at the machine and are fed into a laning system on a conveyor. From the end of this conveyor a layer of tubs is formed and loaded onto the semi-erected wraparound case blank by

HMPS are experts at packaging dairy! Here is an example of HMPS 7100, the high speed automatic casepacker, collect and pack pouches of yoghurt into wraparound cases. The machine has the capability of packing pouches of different volumes and with either a small or a choke proof cap. Packing 5 different sized products at max

A manual adjust HMPS5000 Wraparound Casepacker designed to pack boxes of cheese. Product is conveyed from upstream processes in single file and enters a diverter on the infeed conveyor. The diverter directs the product into one of several lanes depending on demand and the selected packaging configuration

Video of HMPS 1000 Bag in Box Casepacker for Bags of Softserve Icecream. It was designed to pack 10 litre bags of softserve into cartons. The HMPS1000 series of packaging machines are proven systems which offer either semi or fully automatic end of line bag-in-box (BIB) carton packaging for any BIB product

HMPS designed and manufactured a special crate packer for an Australian dairy. Here is a video of the crate packer packing bottled milk. Due to the bottled milk with thinner plastic walls, the handling of the product needed special consideration in order to avoid product damage throughout the packing process. This machine packs twice the